Are you searching for a high-performing Transfer Fusing Machine in Mumbai to carry out heat transfer printing, patch bonding, logo application, or garment interlining? Shri Sai Technic presents to you a top-quality range of Transfer Fusing Machines that are not only technologically advanced but also feature precision, strength, and even heat distribution capability.

Our equipments, which are the best solutions for apparel units, manufacturers of uniforms, printing houses, and exporters of textile, guarantee flawless transfer results due to their consistent heating and efficient pressure control.

Shri Sai Technic – Trusted Transfer Fusing Machine Manufacturer in Mumbai

Shri Sai Technic with a strong hold on more than 22+ years of industry insight is one of the prominent manufacturers of garment finishing and heat transfer equipment in Mumbai. Our company commits to high-quality production since 2002 through:

- Quality-tested raw materials

- High-accuracy engineering

- International quality benchmarks

- Durable industrial parts

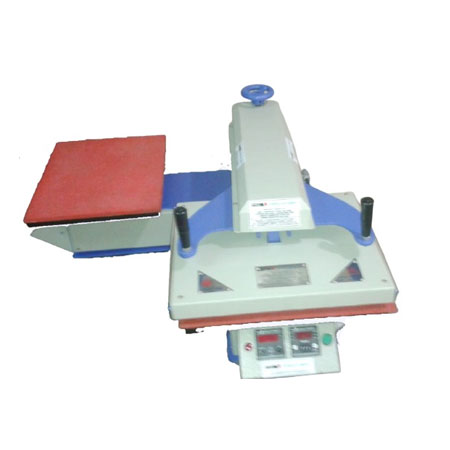

- Transfer Fusing Machine

- Fusing Machine

- Steam Generator

- Vacuum Table

- Stain Removing Table

- Portable Boiler

- Gas Boiler

- Electric Steam Generator

- Fusing Press Machines

The garment exporters and importers, printing houses, boutique manufacturers, and large production units, located not only in Mumbai but also throughout India, are the ones who have faith in our machines.

What Is a Transfer Fusing Machine?

A Transfer Fusing Machine is a device, that can be considered as a special heat press, which transfers images, characters, or any kind of art by means of the control of temperature, and pressure.

- Logos

- Vinyl designs

- Stickers

- Patches

- Labels

- Digital prints

- Interlining

to textile materials. The equipment is capable of delivering clean binding, exact temperature regulation, and great output efficiency.

Why Choose Our Transfer Fusing Machine in Mumbai?

Shri Sai Technic is the company that makes machines that are up to the industrial level which means they can be used for heavy load and continuous work without any problem.

- Uniform Heat Distribution The most efficient transfer is done without burning or tearing the material.

- High-Pressure Mechanism If you want to have the best bonding of patches, logos, and vinyl transfers this device is the right choice.

- Digital Temperature Control Panel The operation is simple, and the temperature is very accurately set for any typeure of garment.

- Energy-Efficient Heating Technology Helps the user by saving money while the quality of the work is kept at the highest level.

- Heavy-Duty Heat Plates These are capable of long-term use and will always give you the same quality of the transfer.

- Fast Heating Time The main reason for this production speed is the quick heating time.

- Compact, Strong, and Industrial-Grade Build The small, medium, and large garment production facilities can use it without any problem.

Single Transfer Fusing Machine

Features

- Teflon Coated even heat Platens

- Air assist for high production

- Automatic Program Cycle For Long Production runs

- Easier Pressure adjustment System

- Tough, Heavy duty machine

- Ideal For high Productivity

- Emergency release Electric System

- Dual Timer Setting

- Production Monitor

Benefits of Using Our Transfer Fusing Machine

Technical Specifications (General Overview)

- Temperature range: 0°C to 250°C

- High-pressure heat plates

- Digital timer & temperature controller

- Industrial-grade heating coil

- Auto-open and pneumatic models available on request

Frequently Asked Questions (FAQ)

Conclusion

If you are looking for a reliable Transfer Fusing Machine in Mumbai, Shri Sai Technic is the one to provide you with the best, sturdy, and high-performing machines made for the contemporary garment and heat-transfer printing industries. We, as a manufacturer, have been made a trusted name throughout Mumbai because of our concern for accuracy, low energy consumption, and durability for a long time.