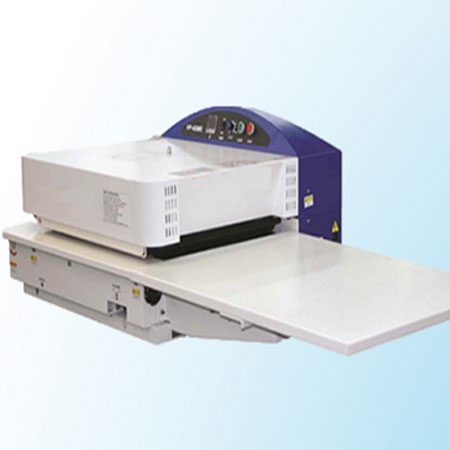

Fusing Machine

A continuous fusing machine is normally used for attaching the interlining with the fabrics. It is one of the important equipment which is significantly used in the garments manufacturing industry. As its importance in the readymade garments sector, today I will present here the features and specifications of a continuous fusing machine.

Features

- Is improved by heating the lower plate.

- During pressing temperature, time and pressures are fully controlled. Continuous Fusing machine is suitable for bulk production due to its continuous process.

- It is consists of a fusing chamber containing a continuous belt or feed sheet.

- Here, the heating chamber is controlled by a switch.

- Continuous fusing machine is widely used in the apparel industry.

- Pneumatic movement of the frames.

- Here, the movable lower plate is heated electrically.

- Continuous fusing m/c has an additional flapper screen.

- It has high effective specific pressure.

- Here, spring or pneumatic power produces the roller pressure and has the condition to increase or decrease of required heat.

- During the movement two flapper screens hold the pieces keeping them in the original position whilst one is under pressing, the other one is in unloading or loading position.

- In continuous fusing m/c, the fusing chamber contains two pressure rollers.

- Banding between the fusing material and the fabric

Fusing Machine Manufacturers in Mumbai

Shri Sai Technic fusing machines are well-known in the market for it’s adjust impute like less maintenance and exceptional superiority. Fusing Machine Manufacturers in Mumbai presented fusing machines are inspected as per market divergent parameters to create certain the complete variety is free from any sort of production defect. We offer premium quality Fusing Machine Manufacturers in Mumbai. It is used for garment fusing particularly made for small units & tailors. Instead of breaker weights this machine is fixed with a lever for necessary working pressure. Our composite molding films are designed to withstand tremendous temperatures while maintaining their release characteristics and are available in a variety of colors to allow for easy identification.

Fusing Machine Manufacturers in Mumbai our customer can also avail from us an elite range of Manual Fusing Machine at antagonistic prices. These manual fusing machines are simple to handle and operate. We also offer modified solution to our clients as per their requirement. Our range is extensively used in dissimilar industries and acknowledged for flat functionality and high performance. Fusing Machine Manufacturers in Mumbai Manual Fusing Machines economic manual heat transfer machine used particular precise winding tube technique, can successful lyguarantee the even and stable temperature. The high temperature and time are wholly controlled by electronic; the signal indication is expedient to use.

Shri Sai Technic is one of the most important organizations, engaged in manufacturing best quality Hot Press fusing machine to our customers as per their requirement. We are having hot press fusing machine for laminating fabrics in clothing, underwear & garments industry. It is one of the main equipment which is considerably used in the garments manufacturing industry. As its effect in the readymade garments sector, today I will present here the features and stipulation of a continuous fusing machine. This machine has a solid structure, extensive scope of submission. It is used for fusing and skill processes textile/garment printing reason. Fusing Machine Manufacturers in Mumbai these products are well thought-out and developed using high-value raw-material and cutting-edge technologies, in agreement with the international superiority parameters.